The Sullair 185 Parts Manual is an essential guide for operators and technicians, providing detailed information on operation, maintenance, and replacement parts․

This comprehensive resource ensures efficient operation, routine maintenance, and safe repair of the Sullair 185 compressor․

1․1 Importance of the Manual for Maintenance and Operation

The Sullair 185 Parts Manual is a critical resource for ensuring the compressor operates efficiently and safely․ It provides detailed instructions for maintenance, repair, and parts replacement, helping users avoid costly downtime․

The manual is essential for identifying and troubleshooting common issues, ensuring optimal performance and extending the compressor’s lifespan․ Regular maintenance, as outlined, prevents premature wear and maintains reliability․

By following the manual, technicians can perform routine inspections, install parts correctly, and address faults promptly․ This reduces the risk of accidents and ensures the compressor meets operational standards․

Key sections include parts inspection, service schedules, and troubleshooting guides․ Adhering to these guidelines ensures the Sullair 185 operates at peak efficiency, safeguarding investment and productivity․

Overview of the Sullair 185 Compressor Model

The Sullair 185 is a portable rotary screw air compressor designed for industrial and construction use, offering high performance, durability, and reliability in demanding environments․

2․1 Key Features and Technical Specifications

The Sullair 185 compressor is equipped with a high-efficiency rotary screw design, offering 185 CFM at 100 PSI․ It features a robust Kubota or Caterpillar engine, ensuring reliable operation in challenging conditions․

The compressor is built with durable components, including a premium-grade oil system and advanced cooling technology, which maximize performance and extend service life․ Its compact, portable design makes it ideal for mobile applications․

Technical specifications include a maximum pressure of 100 PSI, a flow rate of 185 CFM, and a fuel-efficient operation that reduces operating costs․ The compressor is also Tier 4 Final compliant, meeting environmental emissions standards․

Sullair 185 Parts List and Catalog

The Sullair 185 parts list includes essential components like air filters, oil filters, and regulator valves, ensuring easy identification and replacement․ The catalog provides detailed part numbers and descriptions for efficient ordering․

3․1 Essential Components and Their Functions

The Sullair 185 compressor features several critical components that are vital for its operation․ These include the air filter, oil filter, and regulator valve, which ensure clean air intake, proper lubrication, and pressure regulation․ The compressor also includes a screw rotor, which is the heart of the unit, responsible for compressing air․ Additional key parts like the cooling system, control panel, and safety valves work together to maintain optimal performance and safety․ Each component is designed to perform specific functions, ensuring the compressor operates efficiently and reliably․ Regular inspection and maintenance of these parts are crucial to prevent downtime and extend the lifespan of the equipment․ Understanding their roles helps users identify potential issues early and perform necessary repairs or replacements as outlined in the manual․ This ensures the Sullair 185 continues to deliver consistent and high-quality compressed air output․ Proper functionality of each part is essential for meeting operational demands․

Maintenance and Servicing Guidelines

Regular maintenance is crucial for the Sullair 185 compressor, including filter replacements, lubrication checks, and pressure adjustments․ Adhering to the recommended service schedule ensures optimal performance and prevents unexpected downtime․

4․1 Recommended Service Schedule and Procedures

To maintain the Sullair 185 compressor’s efficiency and longevity, a structured service schedule is essential․ Daily checks should include monitoring air filter cleanliness, ensuring proper lubrication, and verifying oil levels․ Weekly inspections should focus on belt tension, hose connections, and coolant levels․

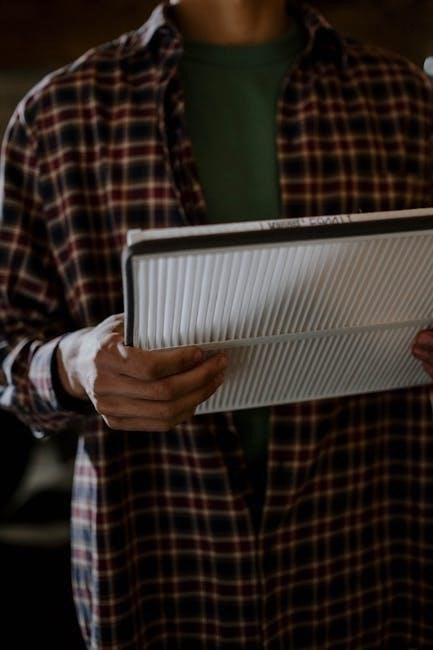

Every 500 hours, replace air, oil, and fuel filters to prevent contamination and wear․ Additionally, inspect and clean the heat exchanger to maintain optimal cooling․ At 1,000-hour intervals, perform a detailed inspection of the rotary screw element and replace it if necessary․

Annual maintenance should include checking the compressor’s electrical connections and testing the pressure relief valves․ Always refer to the Sullair 185 parts manual for specific procedures and genuine replacement parts․ Following this schedule ensures reliable operation and minimizes downtime․ Proper servicing also helps in identifying potential issues early, preventing major repairs․ Regular maintenance is key to sustaining peak performance and extending the compressor’s lifespan․

Troubleshooting Common Issues

5․1 Identifying and Resolving Faults in the Sullair 185

Troubleshooting common issues with the Sullair 185 involves identifying faults, consulting the parts manual for accurate repairs, and following specific procedures regularly to ensure optimal performance and maintain long-term reliability effectively․

Troubleshooting the Sullair 185 compressor involves systematically identifying and addressing common faults to minimize downtime and ensure efficient operation․ The parts manual serves as a critical resource, providing detailed diagnostics and repair procedures․

Common issues include air leaks, filter blockages, and compressor overheating․ These problems often stem from improper maintenance, worn-out parts, or incorrect installation․ Regular inspection of components like the air filter, oil filter, and cooler is essential to prevent malfunctions․

Resolve faults by consulting the manual for specific repair steps, such as replacing faulty valves or cleaning clogged filters․ Adhering to the recommended service schedule helps prevent issues before they arise, ensuring optimal performance and extending the compressor’s lifespan․

By following the troubleshooting guidelines and using genuine Sullair parts, operators can efficiently resolve faults and maintain the compressor’s reliability and efficiency over time․

The Sullair 185 Parts Manual is an essential resource for maintaining, troubleshooting, and operating the compressor․ Adhering to its guidelines ensures optimal performance and long-term reliability․

6․1 Best Practices for Long-Term Efficiency and Reliability

Proper maintenance and adherence to the Sullair 185 Parts Manual are crucial for sustaining peak performance․ Regularly inspecting and replacing air, oil, and fuel filters ensures optimal compressor efficiency․

Operators should follow the recommended service schedule, including checking and replacing worn parts promptly․ This prevents unexpected downtime and extends the compressor’s lifespan․

Additionally, training on the function and installation of Sullair service parts is essential for technicians․ Troubleshooting common issues early can prevent major malfunctions and maintain reliability․

By following these best practices, users can ensure the Sullair 185 compressor operates efficiently, reducing operational costs and enhancing overall productivity over the long term․